Eco-Conscious Packaging: How Suppliers Support Printers’ Sustainability Goals

Every year, PRINTING United Expo brings the printing industry together under one roof. In this venue, printers, converters, vendors, and other industry leaders have the opportunity to learn from each other — and to determine the biggest trends driving the industry forward.

The 2025 event — held Oct. 22-24 in Orlando, Florida — was no different. In fact, Cory Francer, analyst at Alliance Insights, gave packaging and label producers a good idea of what to look out for in his research presentation, which provided a sneak peek of this year’s annual digital packaging report, “Digital Packaging: Maximizing Innovation and Impact.”

One of the top demands from brands, Francer revealed, was sustainability. This has been important to brands for years, but in this year’s survey, brand owners indicated that sustainability requires more than package recyclability.

To meet that demand, package and label printers and converters need to think about their environmental impact on every level — from recyclability and energy usage to waste management.

We spoke with substrate and equipment manufacturers at PRINTING United Expo 2025 to hear their takes on sustainability, as well as get a glimpse of how their companies are evolving to meet printed package and label producers’ needs.

Efficiency Improvements and Waste Reduction

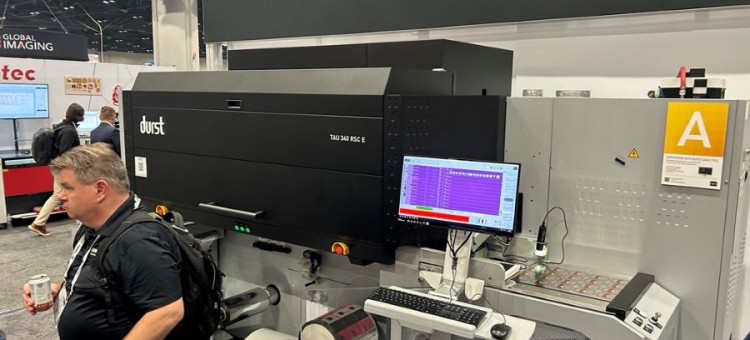

Barry Wendell, national sales manager for the label division at Durst Image Technology, says that efficiency and waste reduction is top of mind when designing equipment.

“The equipment that we manufacture for the label market — digital label presses — already has very short web paths, very minimal waste, and there are features built into the equipment to minimize the low amount of waste that we have even further,” Wendell says. “For example, our customers can reverse the web in the press so that — say, for example, they want to print a proof — they can print that proof, and then they can actually back the material up and then print right behind that proof with the rest of the job, so that they're not wasting any material.”

Household product containers displayed at Yupo’s Expo booth highlight various applications for synthetic labels.

Wendell also adds that the company, a PRINTING United Alliance member, recently announced UV-LED curing technology, which has already been a hit in Europe and is making big strides in the U.S. market — in part because energy costs are up.

“Here, companies are starting to figure that out and starting to look at ways they can reduce their energy costs, reduce their environmental footprint,” he says. “So we're seeing more and more interest in LED curing technology.”

Energy efficiency and waste reduction are also a top priority for Heidelberg, a PRINTING United Alliance member.

“For example, the Gallus One digital label press minimizes setup waste and energy use, while innovations in drying systems for our Speedmaster XL106 machines — such as optimized airflow and heat recovery — cut energy consumption by up to 30%,” Clarence Penge, president of Heidelberg USA, said in an email.

Efficiency and waste cuts don’t stop with equipment; even substrates can make a difference. According to Ryan Kight, marketing manager at Yupo Synthetic Papers, a PRINTING United Alliance member, says several of the company’s products are designed to improve both run time and makeready time.

Recyclable Materials

Recyclability continues to be an important facet of brand owners’ sustainability demands, as Francer revealed in his Expo presentation. With this in mind, Yupo has designed materials to improve recyclability. One such technology is CleanSort.

A sample container at Yupo’s Expo booth features the company’s CleanSort in-mold label technology designed to aid recyclability.

“We've created products from the labeling side of packaging specific to the recyclability,” Kight says. “... We now have a version of in-mold labeling specifically that is removable or liberates itself from a package, so thereby, during the recycling process, the inks, the varnishes, and the foils do not interfere with the package itself. … So we believe that to be fully sustainable, and it's really, really a game changer in the industry.”

Wendell notes that Durst’s equipment can handle a wide range of substrates, including the sustainable ones.

“It's easier for me to tell you what we struggle to print on than what we can print on,” Wendell says. “We can print on a massive variety of substrates, which include all kinds of recyclable materials.”

Meanwhile, Heidelberg has focused its attention on fiber-based substrates, which have the highest recycling rates among all packaging materials.

“This ensures that valuable fiber materials remain in circulation for as long as possible, supporting a more resource-efficient and circular economy,” Penge said in an email. “For this, Heidelberg is adapting its systems and products to support the usage of eco-friendly materials by developing technologies that enable efficient processing of fiber-based packaging. For example, the Boardmaster flexographic press is designed for high-speed production using water-based inks and barrier coatings that enhance recyclability of the printed products.”

Forward-Looking Sustainability Efforts

Package and label printers and converters are certainly looking to elevate their sustainability efforts — and often push their suppliers to help them get there. So, that means substrate and equipment manufacturers must evolve to meet those needs.

For instance, Kight says Yupo keeps an eye on demands, all while staying true to its strengths and goals. The company continues to innovate and create products, such as water-based adhesives, that meet evolving sustainability demands.

Penge notes that Heidelberg’s sustainable innovation doesn’t happen in a vacuum.

“We focus on developing technologies that help reduce resource consumption — such as energy and paper waste — and work closely with partners to co-develop innovative solutions that enable the use of sustainable packaging materials,” Penge said in an email.

At the end of the day, while their customers may ask for it, Wendell says championing sustainability is an imperative for Durst — and for the industry as a whole.

“I think we have a serious responsibility to be the drivers of initiatives to help reduce environmental footprint in everything that we do,” Wendell says. “… Our customers are interested, and they're asking, but I think it's incumbent upon us as manufacturers to be sure that we're innovating constantly, to make sure that we're reducing waste and reducing CO2 and reducing our environmental footprint.”

Kalie VanDewater is associate content and online editor at NAPCO Media.

DIC Group, Xampla Bring PFAS-Free Coatings to Asia

DIC Group, Xampla Bring PFAS-Free Coatings to Asia

Flexo-Printed, Fiber-Based Packaging Deliver Premium Brand Presence for LUPICIA Tea

Flexo-Printed, Fiber-Based Packaging Deliver Premium Brand Presence for LUPICIA Tea

Research: U.S. Businesses Worried About Future Packaging Materials Shortages

Research: U.S. Businesses Worried About Future Packaging Materials Shortages

World Packaging Organisation at COP30

World Packaging Organisation at COP30

NAW Seeks Injunction Against Oregon Packaging Law

NAW Seeks Injunction Against Oregon Packaging Law

Archroma Earns EcoVadis Gold for Second Year

Archroma Earns EcoVadis Gold for Second Year